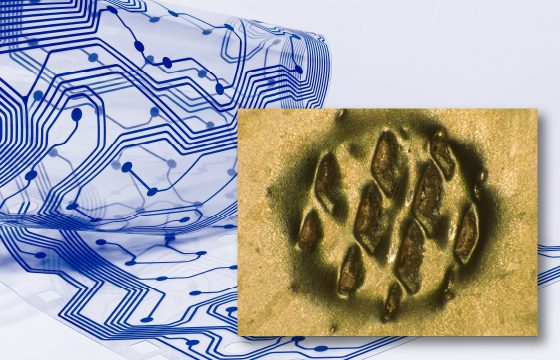

Over 1,000 prototypes and projects! One-stop for solution proposals based on a track record of prototyping for electric vehicles (EV), biosensor substrates, FCVs, medical care, and 5G in the U.S.

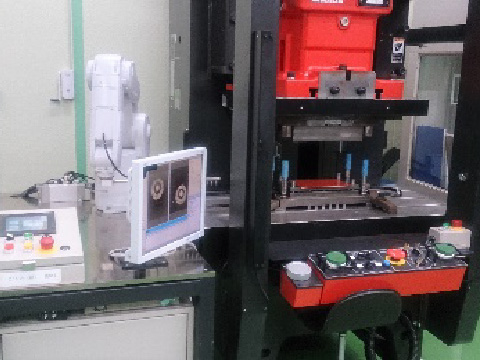

We handle everything from rolling methods to single wafer automatic machines! We propose automation equipment with QCD (Quality, cost, delivery) suitable for mass production projects. We can also propose solutions for many pieces of unique equipment such as machines compatible with 600mm width rolling, and image robot presses.

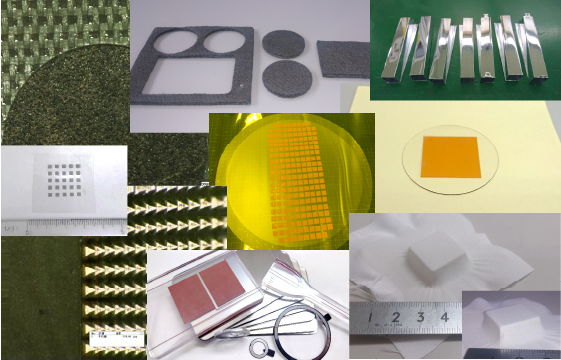

Achievement of punching with positioning accuracy of ±5 μm! Using a mold with a built-in camera (patented method), mass production of high-precision encoder scales is possible through robotic image positioning.

Burr-free punching for copper and aluminum heat dissipation substrates! We employ the fine blanking method used in industries such as automobiles and semiconductors, resulting in punching without burrs or sagging.

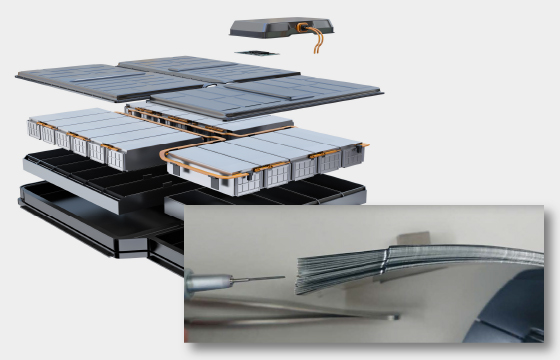

Ultra-thin foil for electrode materials used in rechargeable batteries can also be punched! 10μ aluminum foil can be processed without burrs or coat peeling. In addition, we propose solutions for a drop-out lamination method that is excellent for mass production.

Quality control system philosophy of "100 millionths of zero" with no market complaints Mass production results based on 45 years of technical knowledge of electronic parts, circuit boards, and FPC precision presses. State-of-the-art DX press processing that can handle all traceability data (Smartfac! ©)

We offer overwhelming competitiveness in punch processing as well as in accelerated product development.

Please contact us for anything!

Clean environment ・Servo press

Clean environment ・Servo press In-house developed fully automated robot press device (patented)

In-house developed fully automated robot press device (patented) Factory No.2 complete clean room for press processing

Factory No.2 complete clean room for press processing Digital microscopes for image observation

Digital microscopes for image observation Fully automated robot press line

Fully automated robot press line Image dimension measuring device (wide type)

Image dimension measuring device (wide type) Large Thomson clean room (900×900mm)

Large Thomson clean room (900×900mm) Roll to Roll 600 mm thickness large servo press

Roll to Roll 600 mm thickness large servo press Roll to Roll 400 mm thickness roll press

Roll to Roll 400 mm thickness roll press Roll to Roll 600 mm wide servo roll press

Roll to Roll 600 mm wide servo roll press Large Φ600 mm projector

Large Φ600 mm projector Assembly work site

Assembly work site Camera alignment automated guide drilling machine

Camera alignment automated guide drilling machine Backlight table for large sheet inspection

Backlight table for large sheet inspection Clean room appearance inspection room

Clean room appearance inspection room Packing/lot management system (iPad/Smartfac!)

Packing/lot management system (iPad/Smartfac!) Traceability system (Smartfac! Work database management)

Traceability system (Smartfac! Work database management) In-house developed fully automated appearance inspection device

In-house developed fully automated appearance inspection device

| Company name | Sanko-Giken Corporation |

|---|---|

| Chairman of the Board | Yoshimi Tanaka |

| President and Representative Director | Takeshi Tanaka |

| Established | 01.10.1976 |

| Location | [Head Office] 3-5-38, Tamakushicho Higashi, Higashiosaka Shi, Osaka Fu, 578-0932, Japan [Factory No.2] Next to the main factory (complete clean room press factory) |

| Capital | 20,000,000 yen | Business Activities | 1. Precision pressing, inspection, assembly, (prototyping, development projects, mass production outsourcing) 2. Application development and sales |

| Examples of main processed products | Substrates, precision printed goods (etching), non-ferrous metals, film, precision press processing (drawing, bending, cutting) / precision assembly work / inspection processing | Accredited |      |

| Intellectual property |

2 utility models for roller conveyors Patent for a "Mold with a Built-in Camera + Robotic Positioning Device" Patent for a "Face Shield Realized by 3D Folding Technology" Neck-mounted face shield trademarked "Smile Shield"® Daily work report recording application Trademark registration for "Smafac!"® |